Models:

- BOXMATIC Manual DDCFM-DD – flexo modul Flexomatic – two double die-cut

- BOXMATIC Manual DCFM-D – flexo modul Flexomatic – double die-cut

- BOXMATIC Manual DDC-DD – two double die-cut

- BOXMATIC Manual DC-D – one doubled die-cut (2x100mm)

Purpose of the machine

Semi-automatic corrugated converting machine for production of corrugated boxes, trays, partitions and cut-out parts with the option of additional die-cut (e.g. for handholes) and flexo print (e.g. for company or RESY logo) can also simply cut and crease a cardboard both crosswise and lengthwise. The production of slotted boards (especially series FEFCO 02xx, FEFCO 03xx, etc…) is possible from single-wall, double and triple-wall corrugated boards. Machine can also be equipped with an automatic stacker.

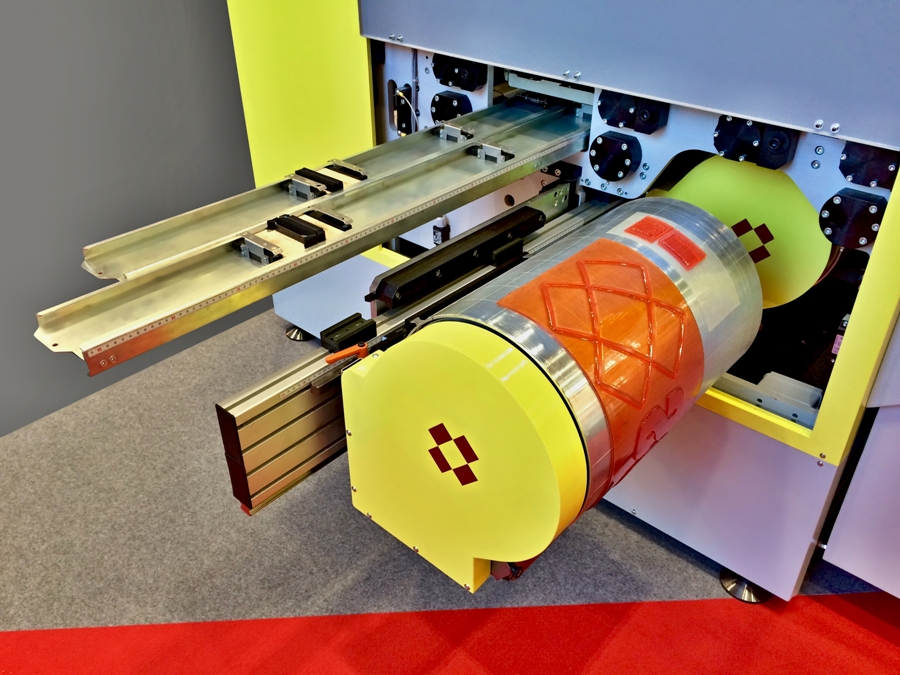

Description

Main parts of the machine – the machine itself, manual loading table. On the output, it can be equipped with a waste bin and automatic stacker. The machine itself then processes cardboard and can perform the following operations:

- crosswise and lengthwise creasing and slotting

- crosswise cutting with the option to simultaneously cut-out flaps

- lengthwise cutting

- supplementary die-cut

- flexo module – large format print

Based on customer´s requirements, this corrugated converting machine can be also equipped with two or three-out production and up to three smart flexo print units. Machine programming and parameter settings are quick and easy thanks to PLC touch panel. Only basic information must be inserted, the rest is calculated by the program itself. Based on the data provided by the program, it is very easy to manually adjust the position of the printing units, die-cut forms, knives, etc. This allows the machine operator to quickly and easily adjust the machine for another job within a few minutes using just one allen wrench.

FEFCO types

- 0200, 0201, 0202, 0203, 0204, 0205, 0206, 0208, 0209, 0214, 0228, 0229, 0230, 0231

- 0300, 0301, 0302, 0306, 0310, 0311, 0312, 0313, 0320, 0325, 0331

- 0400, 0401, 0402, 0403, 0404, 0405, 0406, 0409, 0410, 0411, 0412, 0413, 0442, 0452, 0453, 0454, 0455, 0456, 0458

- 0501, 0502, 0503, 0504, 0505, 0507, 0509, 0510, 0511, 0512

- 0601, 0602, 0605, 0606, 0607, 0608, 0610, 0615, 0616, 0620, 0621

- range 09xx

- and many individual constructions